Wenn es um Räder für den rauen Außeneinsatz geht, dann kommt man an der Kölner Radschmiede Bombtrack nicht vorbei. Seit 2011 produzieren sie neben MTBs und Rennrädern auch durchdachte, robuste und stylische Bikes für die Schotterpisten dieser Welt. Bombtrack genießt schon lange einen ausgezeichneten Ruf in der Szene. Doch Anfang diesen Jahres machten in den sozialen Netzwerken und Foren alarmierende Bilder und Postings von rostbefallenen Rahmen die Runde, die teilweise erst vor wenigen Monaten gekauft worden waren. CLEAT-Redakteur Max Marquardt ist der Sache nachgegangen und bat Bombtrack zum klärenden Interview. Da wir in dieser Sache viele Zuschriften aus dem Ausland erhalten haben, machen wir bei dem Interview eine Ausnahme und haben es in Englisch veröffentlicht.

Hi Jonas, thanks a lot for your time. Through the global pandemic, cycling has become a new trend. Thus, a lot of manufacturers had to struggle and combat the huge customer demands and requests. Especially on delivery bottlenecks ect. So, first: How did you at Bombtrack get thru the pandemic?

Hi CLEAT, no problem, thank you for this opportunity. Well, with the lockdown in the first wave and everything being uncertain back in the beginning of 2020 we have been mostly working from home to stay fully operational. But as we were facing the same supply and shipping issues that already emerged at that time, we have changed our development cycle to adjust for the sudden disruption in the industry. By keeping a lot of bikes untouched, meaning with little or no changes for the next model year we reduced the number of variables that would have worsened an already difficult situation and make everything at least a little more predictable. We are still continuously developing new stuff every day though and try to blend it in to whatever lineup it fits into time-wise.

With the lousy weather conditions approaching, how is it going with your event “NRW Cross Cup”? Will it take place this year and/or is there a backup plan in case it will be postponed?

The NRW Cross-Cup 2021 will follow all current Corona restrictions and will happen as planned. Consisting of 9 races it’s even 3 races more than we used to have, and the anticipation among participants is already high from what we can see at the Cross Cup’s social channels.

Are you planning other events too? Maybe there will be a Bavarian Cross Cup soon?

We have an annual line-up of supported events, some of them require a good amount of work, so there is actually no further headroom for more, Sorry! Especially for 2022 every event will have some significant changes that required extra preparation. In addition to the annual Dirty Boar gravel ride, our annual Groundwork event and another Cross-Cup our schedule for 2022 is already fully booked. But we´re looking forward to all of it!

Let us talk about your framesets and bikes: We were really impressed when we saw the BEYOND series as it remined us on the builds of infamous MTB-racer John Tomac. What was your exact intention on this frame and geometry?

When we designed it, our vison was to make the ultimate touring bike. Wide tires paired with an upright position, a drop handlebar and a geometry that makes you sit “inside” the bike when being in the drops (hope that makes sense, but Beyond riders will know what I mean!) help keep the bike, loaded with racks and pannier bags, sturdy on descents and long flats. It also allows changing positions to help rest the riders body. At the same time we wanted to give the rider offroad capabilities when terrain really gets rough, much like a mountain bike. Mixing all these requirements naturally lead towards the Beyond back then and what is one of our most successful models, being ridden many times around the world now. Despite minor feature, component and geometry tweaks, the model basically still remains unchanged since its introduction in 2016, which I think speaks for itself.

The integrated rear light mount on the Audax is great idea. However, the cable routing is little bit strange as it is located about 10-15 centimeters beneath the mount itself. Also, there is no solution for an internal cable routing on the fork. If you want to mount a hub dynamo you have to use cable ties too. Did you consider these problems when you designed the frame?

The exit of the rear light cable sits at this for one quite simple reason: To prevent a long seat post that´s being inserted too deep to shear off the cable. It is a rather uncommon situation to have such a deep insertion usually, but especially in transportation it might happen quicker than one would expect. The distance between light mount and cable exit is close enough to avoid an additional cable mount.

The EXT fork has an internal cable routing, but you might have noticed that the Audax fork has an axle to crown length typical for a road bike (385 mm), so we can’t just use the same fork as on the Hook EXT without compromising the Audax stack and reach numbers. We are working on an updated Audax fork but changing carbon molds is much more expensive and time consuming than adding a mount on a steel frame. Nevertheless, we think that the rear light cable mount is a feature that is of much benefit for the typical Audax rider, so we didn’t want to wait. Also, especially with cages on the fork it is possible to run the light cable in p-clamps on the fork legs, while light cable routing on the top tube, seat stay, or chain stay is much more obvious and prone to getting damaged.

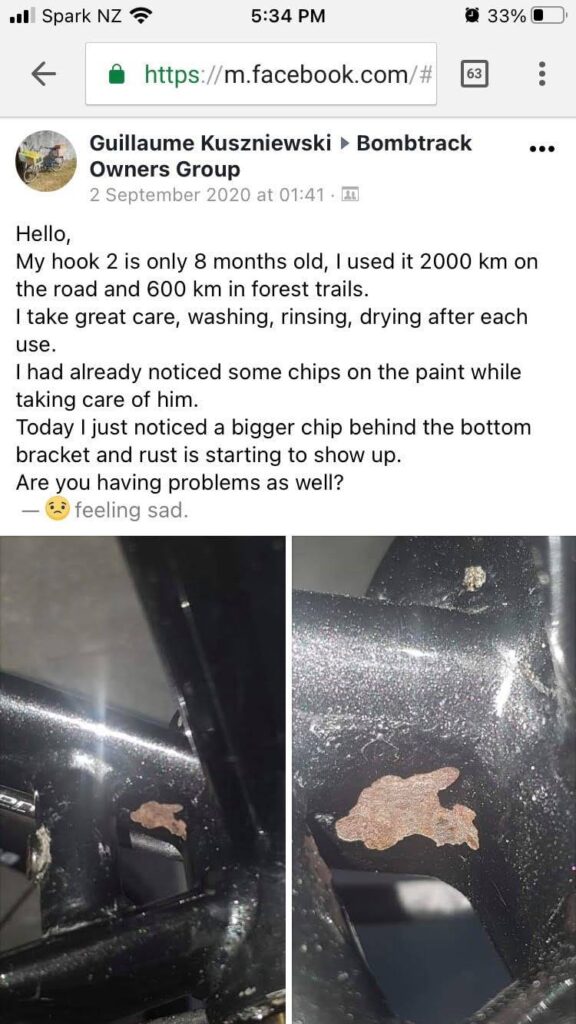

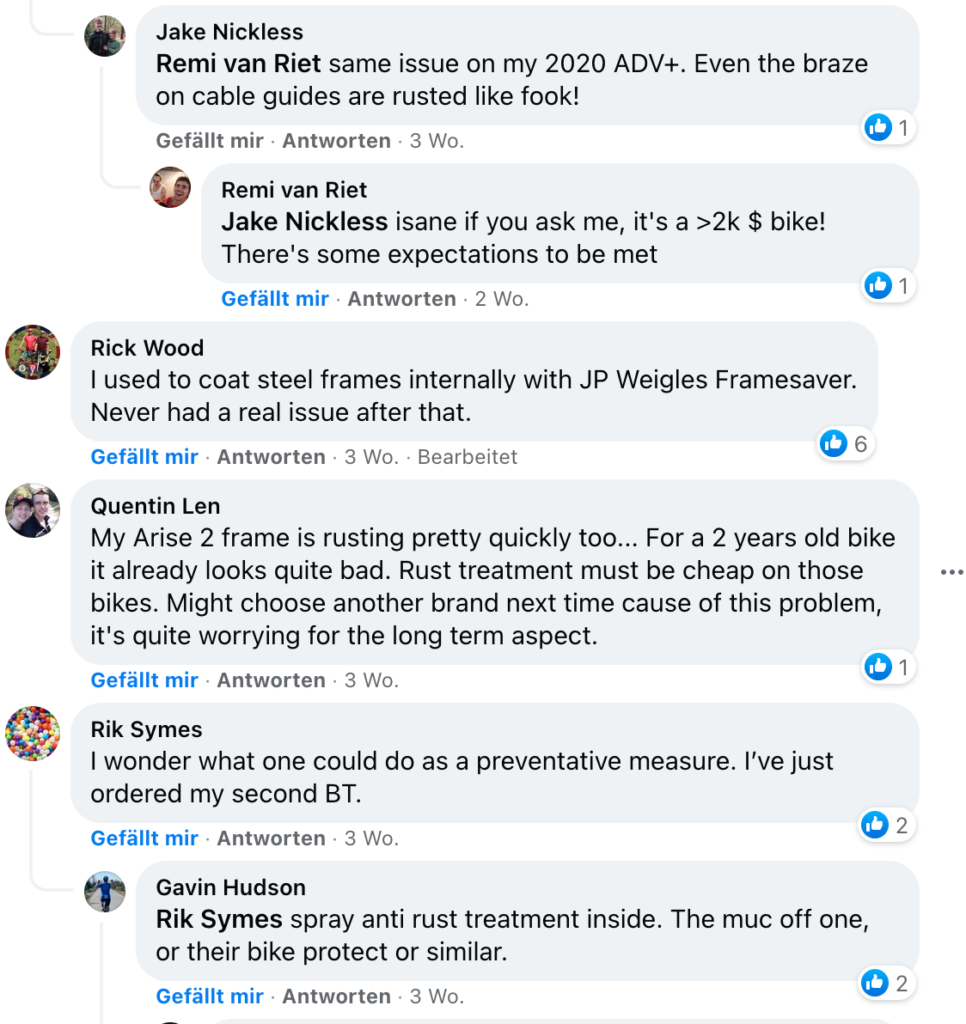

Many riders were arguing on the Bombtrack Owners board lately, about severe rust on their Bombtrack steel frames. We´ve seen plenty of photos of these frames and the riders stated that they were handling their bikes with care and even lubricated the inner tubes with MucOff framesafer and other lubricants. To be honest: Also, my AUDAX has become quite rusty lately. Riding steel bikes for 2 decades now, I am aware of how to handle steel frames. I know that it can rust and it´s quite normal that the seatpost might rust a little if you don´t take care after your bike. But I, and a lot of customers too, where quite shocked when they saw that much rust on their frames after quite a short time period. Also, the pictures are hardcore: Rust on the inside of the tubings, rust on the bottom braket housing and so on. Here are some quotes of the issues:

We know it´s hard to have a remote diagnosis on these issues, however we wonder why relatively new BT frames that are even made of Columbus Chromor tubes are rusting that fast compared to steel bikes made of the same materials (and that are way older). How do you explain these problems? Is it some sort of user failure?

You are right, a remote diagnosis is always hard, furthermore what you have summized above is quite the mix of different situations and observations. So let me try to somehow break it down bit by bit. But first off let me say that in general we can only encourage any customer who feels something is not right with his bike to bring it forward to the dealer he bought the bike from along with any pictures or media. Should there be any concern of a possible warranty issue, it will be brought forward to us through our supply chain and if there is something not right with our products, we will find a solution. It is very hard for us to work things like that through via social media as we feel our customers should get a professional support through our dealers.

Having said that, let me start with the rust in the seat tube:

The seat tube has to be within just 1/10 of a mm in order to properly accept the seat post. This can only be achieved by a reaming tool and the resulting surface has to stay blank afterwards in order to ensure the correct size. Using and regularly changing anti-seize paste or grease on the seat post prevents that from happening and usually we see this complaint where the bike has not been build-up by professional, lacking the knowledge to use such compounds between seat post and frame, especially since these are dissimilar metals and are further prone to galvanic corrosion.

Rust on the outside of the frame, after prolonged use is often caused by paint defects caused by hits from stones, gravel, or similar objects. Left untreated rust that builds in such spots can indeed crawl further under the remaining paint.

Are the inner tubings of BT steel frames somehow “coated” or internally rust proofed?

No, current MY21 models do not have a coating on the tubing inside. This is however a difficult topic we have been discussing for quite some time now and to have a frame fully preserved from the environment is quite a challenge. There are certain methods available, but so far there were none that were satisfactory to implement as they all have disadvantages as well, both for production as well as to the customer. We do know the sight of rust inside the frame might be alarming at first sight, but it usually is just a layer of surface rust. We have yet to see any of our frames to fail due to rust on the inside of the frame. Treating the inside of the frame is as easy as just spraying a cavity wax or oil inside. Basically, every kind of oil spray would work, but wax ones have the advantage of better adhesion. What we could observe though so far is, that most of the more severe sights of rust on our frames have been reported from areas that are close to salt-water coasts. In these climates the air composition contains agents that can heavily accelerate rust buildup, Chlorides in particular. In these climates the story is a little different as this makes for a more aggressive rust development that should be address quickly and kept up regularly. For humide climates that is true as well as the water content in the air is higher.

Nevertheless we have been constantly looking into the subject and further studying options and we´re happy to say that we´ll soon have an internal coating on our steel frames, most likely starting with MY22.

So, how should one handle BT steel frames in order to prevent rust?

For the painted surfaces on the outside a simple clear coat touchup paint will do. Just make sure to remove any rust prior to that. You could also just wipe down those spots regularly with some mineral oil based polished, which is something I personally do on some spots on my frames and on the rest as well. Of course, implies a little more discipline, but it pays up as the polish helps to preserve the paint, dirt won´t stick as good to it and you get rid of any humid environment that could crawl under the tiniest scratch of paint. For the inside, as already mentioned, a cavity wax spray or oil spray can be used. Basically, anything that is oil and covers the surface will do as it separates the steel from water (air humidity). It actually surprises us to hear that customers reported this not helping with our frames, we´d simply suggest to try a different product. There are lots of good ones available from the automotive sector.

Steel frames have become en vogue again. The material is way robust/rugged, provides a certain stiffness and new steel bikes are not that heavy than they used to be in the old days. Also, the material is way sustainable than Carbonfibre. Can we speak of a renaissance of steel today? Or are people still demanding aluminium and carbonfibre bikes?

Oh yeah, indeed. Especially for Gravel and Adventure bikes where robustness and ease of repair come before weight, steel is a very popular choice by now. We do see a lot of riders either getting on their first bike being a steel bike or riders who always had Aluminium or Carbon fiber making the swap. When we started the brand, we offered steel and Aluminium bikes and later added Carbon bikes. Each material has its own specific properties that help adapt it to a specific use case and we do see demand for all of them amongst our riders. Where one customer seeks a sturdy bikepacking / adventure bike that forgives a lot, steel is the go-to choice. Then we have more race-oriented riders who don´t necessarily carry lots of luggage most of the time and do seek lighter weight, those would usually go for carbon or aluminium. But still, steel is our most sold frame material.

With the new season approaching, what are your plans for 2022? Can you give us a glimpse on what is going on at Bombtrack? Is there any exciting news concerning new bikes and framesets yet?

As mentioned in the beginning, we had to cut back a little on the new product development for MY22. So, you will see a lineup that is very familiar, although it will see some new products, colors and tweaks here and there. But since these more uncertain times lie behind us already, we´re back at our usual pace and have loads of ideas in the pipeline already.

Thanks for your time, Jonas! Ride on!